Why Nursery Trays Are Essential for Modern Plant Nurseries

2026-01-28 00:08:28

In today’s fast-evolving horticulture industry, efficiency, consistency, and plant health are more important than ever. One of the most fundamental tools supporting modern cultivation is the nursery trays system. From commercial greenhouses to landscape projects, nursery trays improve propagation success while reducing labor, waste, and growing time.

Professional nursery trays Manufacturer and Factory Production systems now allow large-scale growers to source durable, uniform, and reusable trays that support high-volume planting operations. As plant nurseries expand to meet global demand, nursery trays are no longer optional—they are essential infrastructure for modern agriculture.

This article explains how nursery trays work, why they matter, and how factory-level production improves performance, sustainability, and scalability.

What Are Nursery Trays and How Do They Work?

Nursery trays are structured containers designed to hold growing media and young plants during the early stages of cultivation. They typically feature multiple cells that separate seedlings, ensuring each plant receives balanced water, nutrients, and airflow.

Modern nursery trays are usually made from durable plastic materials engineered for repeated use. Their uniform cell design allows growers to control root development, moisture retention, and transplant success. Instead of scattering seeds in open soil, nurseries rely on trays to achieve precision and consistency.

With factory-based production, manufacturers ensure every tray meets standardized dimensions, strength, and drainage performance, which improves planting efficiency across commercial operations.

Improving Germination and Plant Health

One major advantage of nursery trays is better germination control. Each cell supports a single seedling, preventing competition between plants. This improves early-stage growth and reduces root entanglement.

Because nursery trays regulate spacing, moisture, and airflow, plants grow more evenly and develop stronger root systems. Healthy roots lead to higher survival rates when seedlings are transplanted into larger containers or open fields.

For modern nurseries focused on large-scale output, reliable nursery trays Manufacturer production helps ensure that every tray performs consistently from batch to batch.

Efficiency and Labor Savings for Nurseries

Labor efficiency is a critical factor in nursery management. Without structured planting systems, workers spend extra time thinning seedlings, correcting spacing, and replacing damaged plants.

Nursery trays streamline these tasks by organizing plants in uniform patterns. Automated irrigation, fertilization, and transport systems integrate easily with trays, reducing manual handling. Workers can move hundreds of seedlings at once instead of individually handling plants.

Thanks to factory-level production, nursery trays are designed for stacking, transporting, and mechanized use, allowing nurseries to scale faster while lowering operational costs.

Supporting Large-Scale Production Operations

Modern plant nurseries rarely operate on a small scale. Whether producing ornamental plants, vegetables, forestry seedlings, or landscaping materials, operations depend on predictable output.

High-capacity nursery trays Factory Manufacturing ensures consistent tray quality for bulk supply. Uniform size and material strength allow automated planting lines, conveyor systems, and storage racks to function properly.

When nurseries rely on professional manufacturer production rather than random suppliers, they reduce breakage, material waste, and replacement costs over time. This creates a stable growing environment for long-term expansion.

Root Structure and Transplant Success

Root development is one of the most important factors in plant survival. Nursery trays are engineered with drainage holes and airflow channels that guide roots downward instead of circling.

This structure prevents root binding and improves oxygen exchange. When seedlings are transplanted, intact root balls remain stable, reducing shock and improving establishment in soil.

A reliable nursery trays Manufacturer Production process ensures precise cell geometry, which directly influences root health and transplant performance across thousands of plants.

Durability and Reusability Advantages

Modern nursery trays are not disposable tools. Professional production focuses on durability, chemical resistance, and UV stability. This allows trays to withstand repeated watering, cleaning, transportation, and outdoor exposure.

Reusable trays reduce waste and operating costs. Instead of constantly replacing low-quality containers, nurseries benefit from long service life and predictable performance.

Factory-supplied nursery trays go through quality control checks that verify material thickness, flexibility, and load capacity, ensuring they maintain shape even under heavy planting loads.

Sustainability and Resource Optimization

Sustainability is now a major concern for plant nurseries worldwide. Nursery trays help optimize water usage by directing moisture precisely to root zones rather than wasting it through open soil irrigation.

They also reduce substrate waste and improve fertilizer efficiency. Instead of spreading nutrients across large areas, growers target each plant cell accurately.

With professional nursery trays Factory Production, materials are increasingly recyclable and environmentally optimized, supporting green practices while maintaining commercial performance.

Customization for Different Crops

Different crops require different growing conditions. Nursery trays come in multiple cell sizes, depths, and layouts for vegetables, flowers, forestry plants, and landscaping species.

Shallow cells suit leafy greens, while deeper designs support trees and shrubs. Manufacturers adjust mold design and material composition based on crop requirements.

Working with a reliable nursery trays Manufacturer allows nurseries to select tray specifications that match plant types, growth cycles, and transplant schedules for maximum efficiency.

Why Manufacturer and Factory Supply Matters

Choosing factory-direct nursery trays provides several benefits:

·Stable bulk production capacity

·Consistent quality control

·Better material performance

·Reduced replacement frequency

·Long-term cost savings

Instead of sourcing random trays, modern nurseries depend on professional nursery trays Production and Factory Supply systems to support year-round growing operations without interruption.

Reliable production also ensures fast delivery, scalable expansion, and standardized compatibility with automated nursery equipment.

Conclusion: Nursery Trays as the Foundation of Modern Nurseries

In modern plant nurseries, success depends on efficiency, consistency, and plant health. Nursery trays serve as the foundation of propagation systems by improving germination, strengthening roots, reducing labor, and supporting large-scale production.

With professional nursery trays Manufacturer and Factory Production, growers gain reliable tools that enhance sustainability, reduce costs, and maximize output. From seed to transplant, nursery trays play a critical role in every stage of modern horticulture.

For nurseries aiming to grow smarter, faster, and stronger, investing in high-quality nursery trays is no longer optional—it is essential for long-term success.

References

GB/T 7714:McGrath D, Henry J, Munroe R, et al. From propagation to field: Influence of tray design on tree seedling quality and performance[J]. Journal of Environmental Horticulture, 2021, 39(1): 33-40.

MLA:McGrath, Darby, et al. "From propagation to field: Influence of tray design on tree seedling quality and performance." Journal of Environmental Horticulture 39.1 (2021): 33-40.

APA:McGrath, D., Henry, J., Munroe, R., & Williams, C. (2021). From propagation to field: Influence of tray design on tree seedling quality and performance. Journal of Environmental Horticulture, 39(1), 33-40.

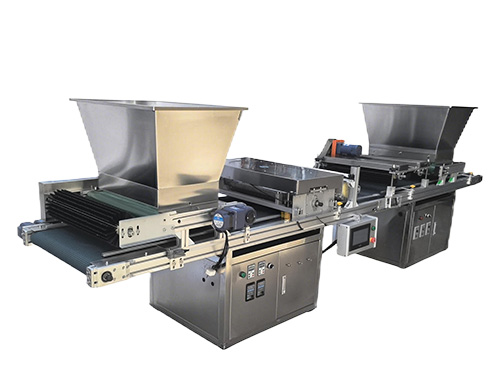

The CNC Seed Braiding Machine is a high-precision, fully automated agricultural equipment s...

It adopts electrical integration and can be started by pressing the fully automatic button ...

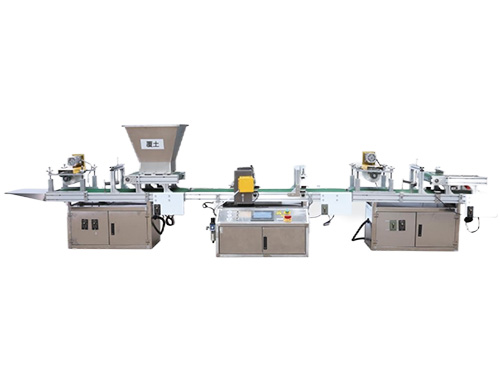

The XP750 seeder has stable performance, excellent product quality, simple and convenient o...

It adopts electrical integration and can be started by pressing the fully automatic button ...