Seed Trays for Herbs and Microgreens: A Specialized Setup

2026-01-15 11:19:45

As a professional seed trays manufacturer with reliable production capacity and bulk supply capability, we understand that successful herb and microgreen cultivation begins long before harvest. One of the most critical yet often overlooked components is the seed tray.

Herbs and microgreens have unique growth characteristics that demand a specialized setup. From shallow root systems to rapid growth cycles, these crops require seed trays designed for precision, consistency, and efficiency. This article explores how specialized seed trays support optimal growth, key design considerations, and why manufacturer-level production expertise plays a vital role in large-scale supply.

Why Herbs and Microgreens Require Specialized Seed Trays

Herbs and microgreens differ from traditional crops in both scale and sensitivity. They are typically grown in dense patterns and harvested at an early stage, making uniform growth essential.

Specialized seed trays help by:

Providing consistent cell depth

Ensuring proper root aeration

Supporting uniform moisture distribution

Manufacturers with experience in seed tray production design trays that align with the biological needs of these fast-growing plants.

Understanding Seed Tray Cell Design

Cell size and shape are crucial factors when selecting seed trays for herbs and microgreens. Shallow, evenly spaced cells are often preferred because they:

Promote rapid root establishment

Prevent excessive root binding

Allow easy harvesting

During production, precise mold design ensures uniform cell dimensions, which directly impacts crop consistency across large batches.

Material Selection for Seed Trays

The materials used in seed tray manufacturing affect durability, hygiene, and plant health. Common materials include high-quality plastics designed for repeated use and easy cleaning.

Key material considerations include:

Resistance to cracking or deformation

Smooth surfaces to reduce pathogen buildup

Compatibility with automated production systems

Manufacturers producing seed trays in bulk prioritize material consistency to maintain performance across multiple production cycles.

Drainage and Moisture Control

Proper drainage is essential for herbs and microgreens, as excess moisture can lead to fungal growth and poor root development.

Specialized seed trays incorporate:

Strategically placed drainage holes

Even water flow across the tray

Compatibility with bottom-watering systems

These features are often refined through production testing to ensure reliable performance under commercial growing conditions.

Optimizing Space and Yield

Herb and microgreen operations often operate in limited space, such as indoor farms or greenhouse racks. Seed trays designed for efficient space usage help maximize yield per square meter.

Benefits include:

Uniform tray dimensions for stacking

Lightweight construction for easy handling

Compatibility with standard shelving systems

Manufacturers with scalable production processes ensure tray dimensions remain consistent across bulk orders, supporting smooth workflow integration.

Supporting Automation and Large-Scale Production

As herb and microgreen production scales up, automation becomes increasingly important. Seed trays must be compatible with automated seeding, watering, and harvesting equipment.

Manufacturer-level design advantages include:

Standardized tray profiles

Reinforced edges for machine handling

Precision manufacturing tolerances

These factors reduce downtime and improve efficiency in automated production environments.

Hygiene and Reusability Considerations

Maintaining cleanliness is critical in herb and microgreen production due to their short growth cycles and direct consumption.

Well-designed seed trays support hygiene by:

Allowing easy cleaning and sanitization

Minimizing debris accumulation

Maintaining structural integrity after repeated use

Manufacturers with controlled production environments test trays for durability and sanitation compatibility before large-scale supply.

Why Manufacturer-Level Production Matters

Not all seed trays deliver the same performance. Choosing seed trays from a manufacturer with established production expertise and bulk supply capability ensures consistent quality, reliable availability, and long-term usability.

Key manufacturer advantages include:

Stable production capacity for large orders

Quality control across every production batch

Customization options for specific crops or systems

These factors are especially important for commercial growers and distributors.

Conclusion

Understanding the role of seed trays for herbs and microgreens is essential for achieving consistent growth and high yields. From cell design and material selection to drainage and automation compatibility, a specialized setup can significantly improve production outcomes.

As a seed trays manufacturer with scalable production and bulk supply capabilities, focusing on precision manufacturing, durable materials, and standardized design ensures that seed trays meet the demands of modern herb and microgreen cultivation. Investing in the right seed trays is a foundational step toward efficient, hygienic, and sustainable production.

References

GB/T 7714:Resh H M. Hydroponic food production: a definitive guidebook for the advanced home gardener and the commercial hydroponic grower[M]. CRC press, 2022.

MLA:Resh, Howard M. Hydroponic food production: a definitive guidebook for the advanced home gardener and the commercial hydroponic grower. CRC press, 2022.

APA:Resh, H. M. (2022). Hydroponic food production: a definitive guidebook for the advanced home gardener and the commercial hydroponic grower. CRC press.

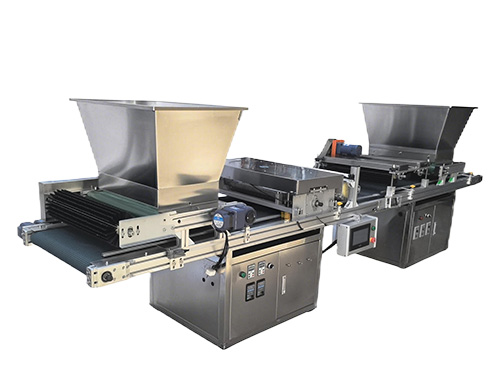

The CNC Seed Braiding Machine is a high-precision, fully automated agricultural equipment s...

It adopts electrical integration and can be started by pressing the fully automatic button ...

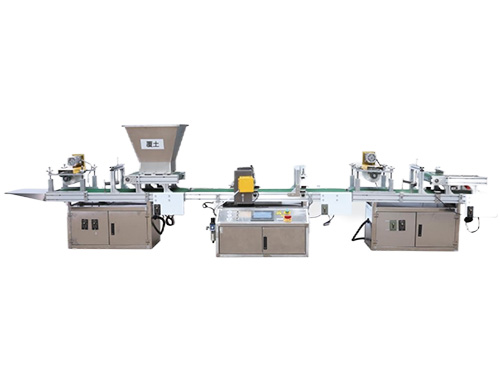

The XP750 seeder has stable performance, excellent product quality, simple and convenient o...

It adopts electrical integration and can be started by pressing the fully automatic button ...